Tutorial 9 - Acoustic Leak Detectors

Acoustic leak detection has become more prominent in recent years. The devices “listen” for ultrasonic frequencies of gas leaks which is outside the range of human hearing. When a gas leak occurs a pressure wave will propagate from the source throughout the facility, the acoustic detector will alarm if the pressure wave is above a specified threshold.

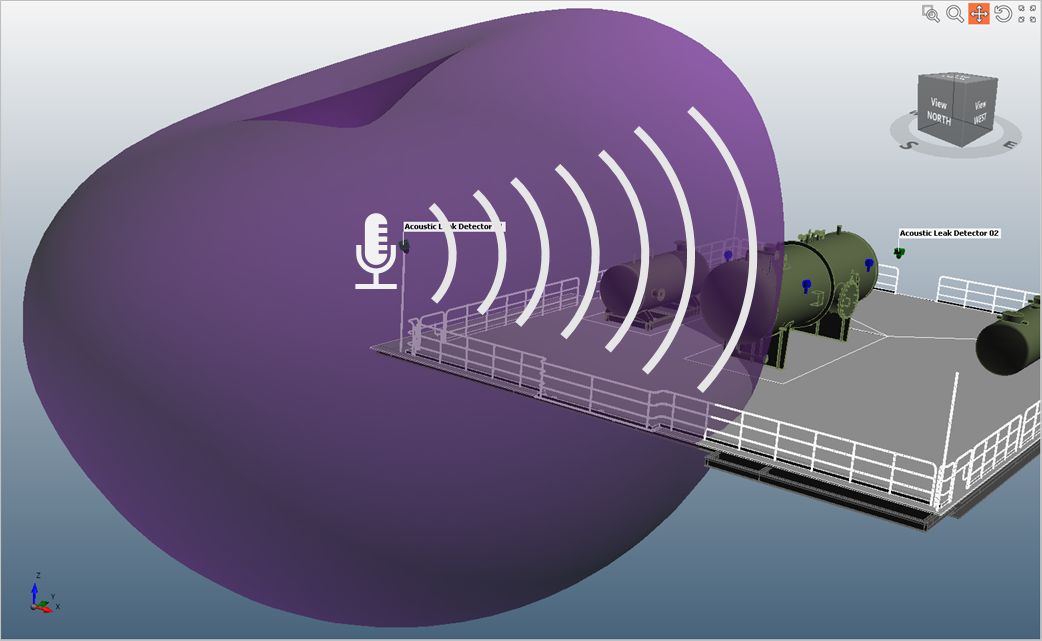

Most of the acoustic detectors make use of high end microphones or piezoelectric sensors to detect this pressure wave. Due to the nature of the microphone's sensor a polar plot resembling a circle or apple shape (shown above) is used to describe the range of hearing of the acoustic detectors, which is normally provided by manufacturers.

Detect3D allows for users to enter information to define this polar plot to simulate the range of hearing for the acoustic detector. Most standards suggest to have an acoustic assessment or similar for the facility prior to installation to determine the level of background noise for your facility.

Learning objects for this tutorial include how to:

-

Add an acoustic detector to a project

-

Compare the results from the combined ultrasonic leak mapping and combustible gas mapping

Files used in this tutorial:

-

Tutorial 2.d3d (< 1 MB) - included in the Detect3D Tutorials.zip (22MB)

Contents of Tutorial 9: